A contactor is an electrically controlled switching device used to control the flow of electricity in a power circuit. It functions much like a relay but is designed specifically for higher current loads, making it ideal for switching electric motors, lighting systems, heating equipment, and other electrical loads in both industrial and commercial applications.

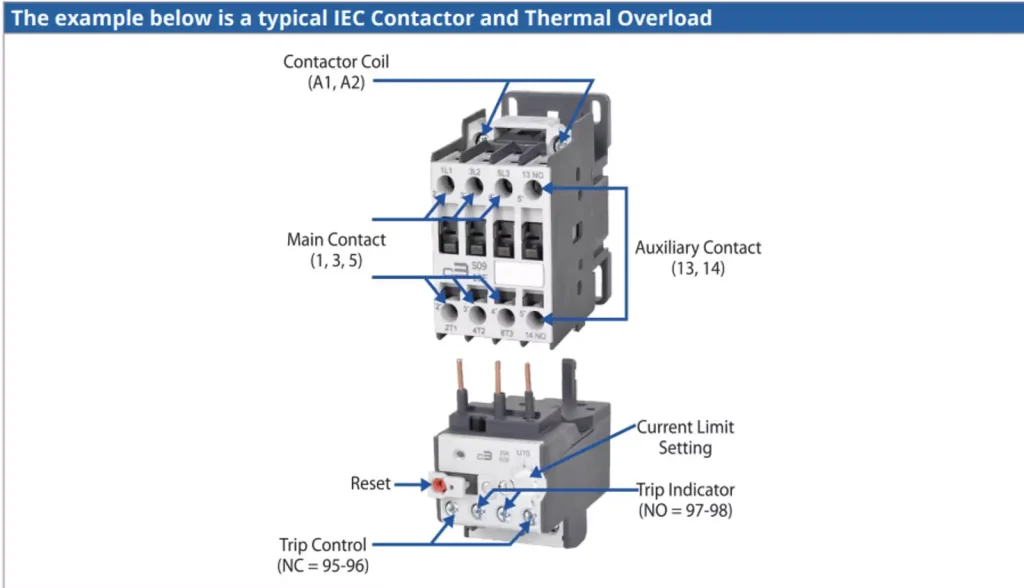

At its core, a contactor is a type of electromagnetic switch. It typically consists of three main components: the coil (or electromagnet), contacts, and enclosure. When voltage is applied to the coil, it generates a magnetic field that pulls a set of contacts together, allowing current to flow through the circuit. Once the coil is de-energised, the magnetic field collapses, and a spring mechanism returns the contacts to their original open state, breaking the circuit.

The contacts within a contactor are generally divided into two categories: power contacts and auxiliary contacts. Power contacts handle the high current flow to the load, while auxiliary contacts are used for control and signalling within a circuit—often providing feedback to control systems or interfacing with other devices.

One of the key characteristics that distinguishes a contactor from other types of switches is its ability to handle frequent switching operations. Contactors are built to withstand thousands—even millions—of cycles, which is critical in applications where loads are frequently turned on and off. In contrast, manual switches or circuit breakers are not designed for repetitive switching and may wear out quickly under such conditions.

Contactor ratings are usually defined by their voltage, current capacity, and duty cycle. They are also categorised according to international standards such as IEC (International Electrotechnical Commission) or NEMA (National Electrical Manufacturers Association), which specify operational characteristics and performance requirements. The most common types of contactors are AC contactors, used for alternating current systems, and DC contactors, which are designed for direct current applications.

A significant advantage of contactors is the ability to control a large electrical load with a relatively small input signal. This makes them an essential component in automated control systems, where they are often triggered by timers, sensors, programmable logic controllers (PLCs), or manual pushbuttons.

In terms of safety and protection, contactors are often used in conjunction with overload relays and fuses or circuit breakers. The overload relay protects the connected equipment from sustained overcurrent conditions, while fuses or breakers guard against short circuits.

In summary, a contactor is a vital electrical component used for controlling power circuits. Its electromagnetic mechanism allows for fast, reliable switching of electrical loads, especially in industrial settings where high current and frequent operations are common. By separating the control circuit from the load circuit, contactors provide both convenience and safety, making them indispensable in modern electrical and automation systems.